What do you know about 3D printed buildings? Why should this matter to you? Well, for starters, some printers can print a 650-square foot house in under 24 hours. These printers use a concrete mix and leave openings for doors and windows. Currently, the cost for this particular house is around $10,000, but it is believed the cost could get down to $4,000. This is huge for the housing industry and is going to make an unbelievable difference in underdeveloped communities.

3D printing is going to explode into the construction industry. Not only is it going to bring new opportunities for just houses and buildings, but other structures like bridges and airplane parts. 3D printing may have the capabilities to print these large-scale structures, but the reality is it is probably going to be used for printing specific components for jobs, such a large steel beams in the near future. 3D printing provides a safer work environment, reduces labor costs, and is able to print things faster than they could’ve been built.

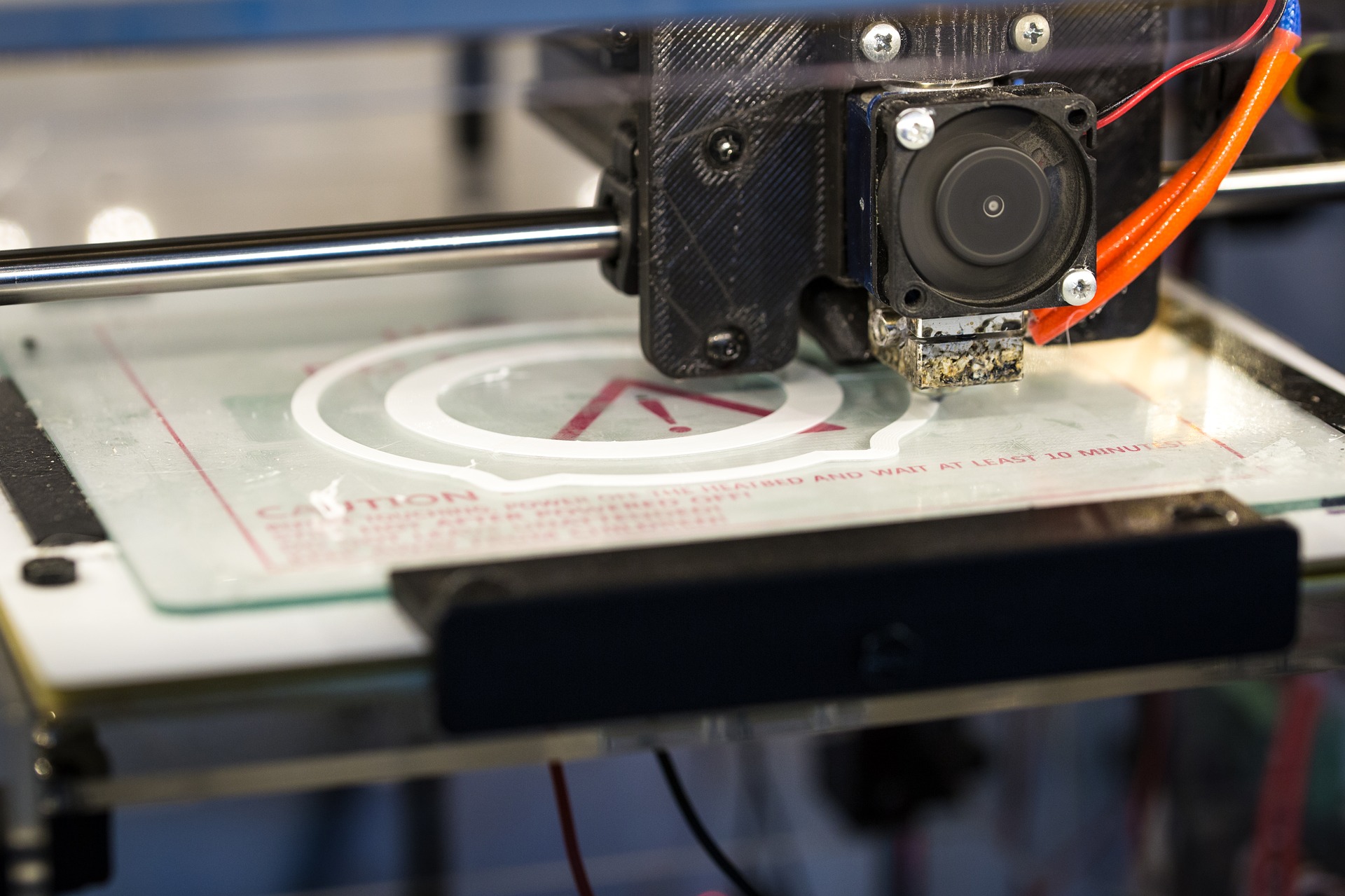

Much of the construction of parts for buildings and other large structures are going to be moved into a factory where there is a 3D printer that can print large pieces of flooring or walls in a more efficient way then they could have been built on site. Some printers may even be on site building materials or structures that are going to be built more efficiently than ever before. 3D printing allows less material to be used when making structures, saving money not only on the labor but in materials as well. The advances being made with these printers are endless. They can print in a variety of materials such as concrete, metals, and metal mixes.

As testing continues, and advancements are made, people are going to start participating in 3D printing. Many governments are on board looking towards 3D printing as a solution for their underdeveloped communities. Others are looking into building military barracks with it using local materials. We may not be seeing entire cities put up by 3D printers just yet, but soon enough it’s going to be possible.

Midsouth Mechanical has been doing business for over 25 years. We offer our industrial clients efficient and cost-effective fabrication, modification, and repair of industrial equipment. From preventive plant maintenance, designing, installing and aligning machines, our exceptional skill and craftsmanship set us apart from the competition. Our number one priority day today is safety. To see our published weekly Toolbox Talks, follow us on LinkedIn, Twitter, or Facebook.