Millwrights work in factories, power plants and other industrial settings to move, assemble, install, or dismantle machinery. They are incredibly skilled at their job, understanding how several different machines work after reading complicated technical plans. Millwrights also repair worn or broken parts.

Before starting the work on-site, millwrights need to go through the plans or blueprints with the supervisor and understand what is expected from them and where the work needs to be done. They also need to go through the selection of tools and equipment required to do the job to ensure that they are well prepared to start the work.

Knowing how to read and interpret plans and blueprints and how to utilize the relevant equipment is extremely important. Millwrights work with a variety of industrial machines and equipment. These machines can be found in manufacturing plants, food processing facilities, mines, and energy plants to mention a few, and working with this machinery requires skill and precision.

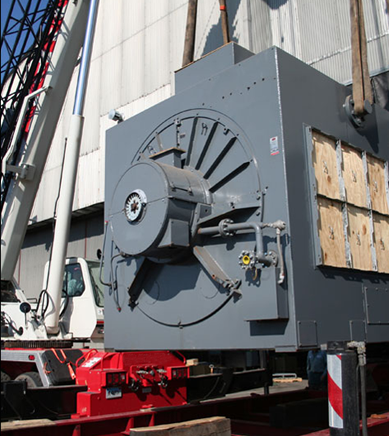

Our millwrights read blueprints and schematic drawings to determine work procedures, to construct foundations for and to assemble, dismantle and overhaul machinery and equipment, using hand and power tools and to direct workers engaged in such endeavors. We have lathes, milling machines, and grinders if we need to make customized parts or repairs. In the course of work, we can move, assemble, and install machinery and equipment such as shafting, precision bearings, gearboxes, motors, mechanical clutches, conveyors, and tram rails, using hoists, pulleys, dollies, rollers, and trucks.

Our team can service you in all your millwright needs. Call us today at 706-884-3206 for further information!

Get a free quote today!