Maximizing Efficiency with Advanced Process Piping Solutions

Critical Components

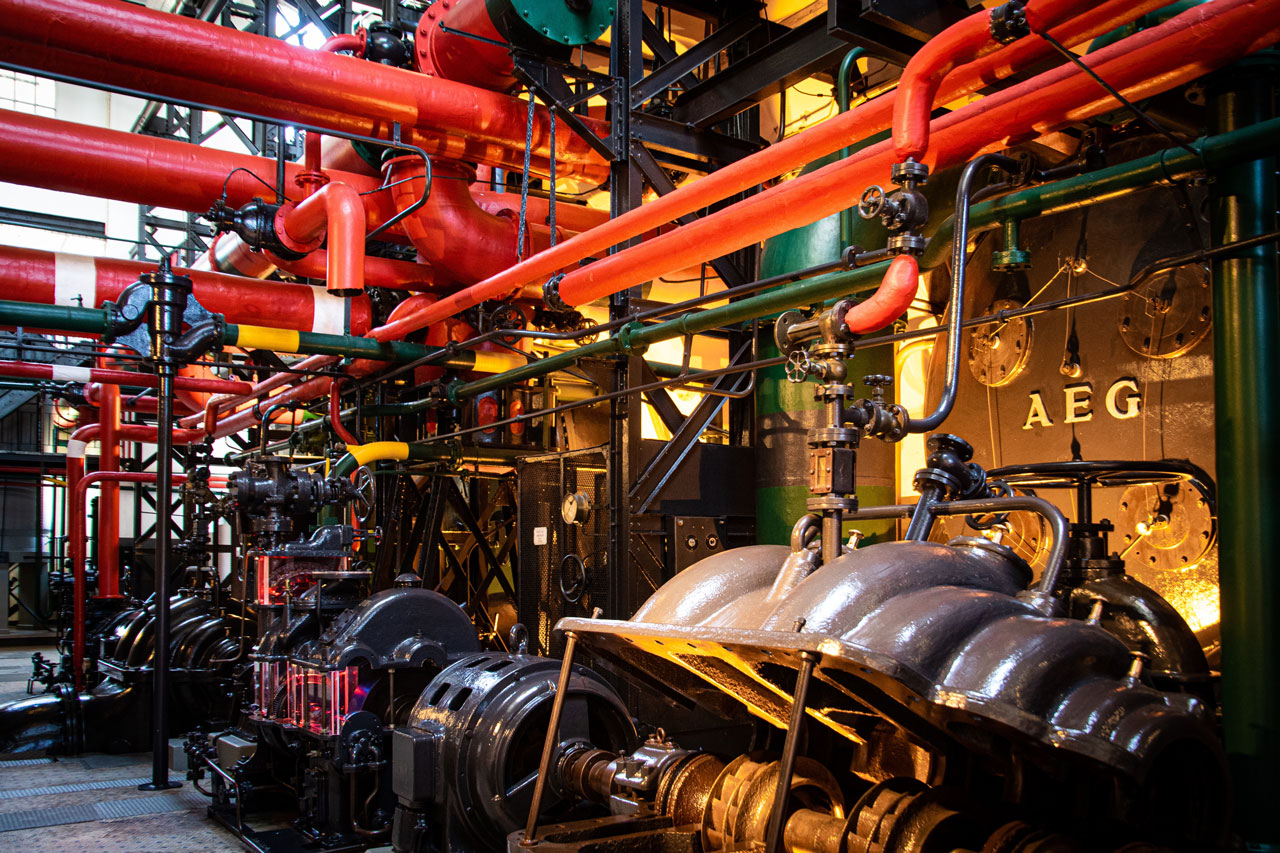

In the industrial world, the backbone of any manufacturing or processing facility is its process piping system. These intricate networks of pipes are not just conduits for moving materials; they are critical components that influence the overall efficiency, safety, and productivity of operations. An optimally designed process piping system can significantly enhance operational capabilities, reduce downtime, and contribute to substantial cost savings. This article explores how advanced process piping solutions can transform your facility, focusing on layout optimization, material selection, and the integration of smart monitoring systems.

The Importance of Layout Optimization

One of the first steps in optimizing your process piping system is the strategic planning of its layout. An effective layout ensures minimal travel distance for materials, which reduces pressure drops, energy usage, and the potential for wear and tear. It also simplifies maintenance and enhances the safety of the operation by reducing congestion and the risk of accidents. Midsouth Mechanical utilizes state-of-the-art CAD software and 3D modeling to simulate and visualize piping layouts before installation. This approach allows for meticulous planning and adjustments prior to construction, ensuring the system is as efficient as possible from the start.

Selecting the Right Materials

The choice of materials in process piping construction plays a pivotal role in the system’s performance and longevity. Each material offers different benefits and is suited to specific types of operations based on factors such as temperature, pressure, and the nature of the substances being transported. For example, stainless steel is favored for its resistance to corrosion and heat, making it ideal for the food and pharmaceutical industries. On the other hand, PVC piping might be used where chemical resistance and lower costs are priorities. Midsouth Mechanical’s experts are adept at navigating these choices, ensuring that each piping system is built with materials that best suit the client’s operational requirements and budget constraints.

Integrating Smart Monitoring Systems

In today’s digital age, integrating smart monitoring systems into process piping designs is becoming increasingly prevalent. These systems provide real-time data on the operation of the piping network, including flow rates, pressure changes, and potential leaks. By leveraging IoT technology, facilities can predict maintenance needs, preventing costly downtime and extending the lifespan of the piping system. Midsouth Mechanical incorporates these smart systems into process piping networks, enabling a proactive maintenance approach and ensuring continuous operational efficiency.

Key to Success

A well-thought-out process piping system is crucial for the success of any industrial facility. By focusing on optimal design, appropriate material selection, and the integration of advanced technologies, facilities can achieve higher efficiencies and cost savings. Midsouth Mechanical is dedicated to providing cutting-edge process piping solutions that meet these goals and support the complex needs of modern industries.

Are you looking to enhance your facility’s efficiency with advanced process piping solutions? Contact Midsouth Mechanical today to discuss how we can tailor a system to meet your specific operational needs and drive your business forward.

Our team is here to help.

Contact a project manager today!