The Role of Mechanical Contractors in Process Piping Systems

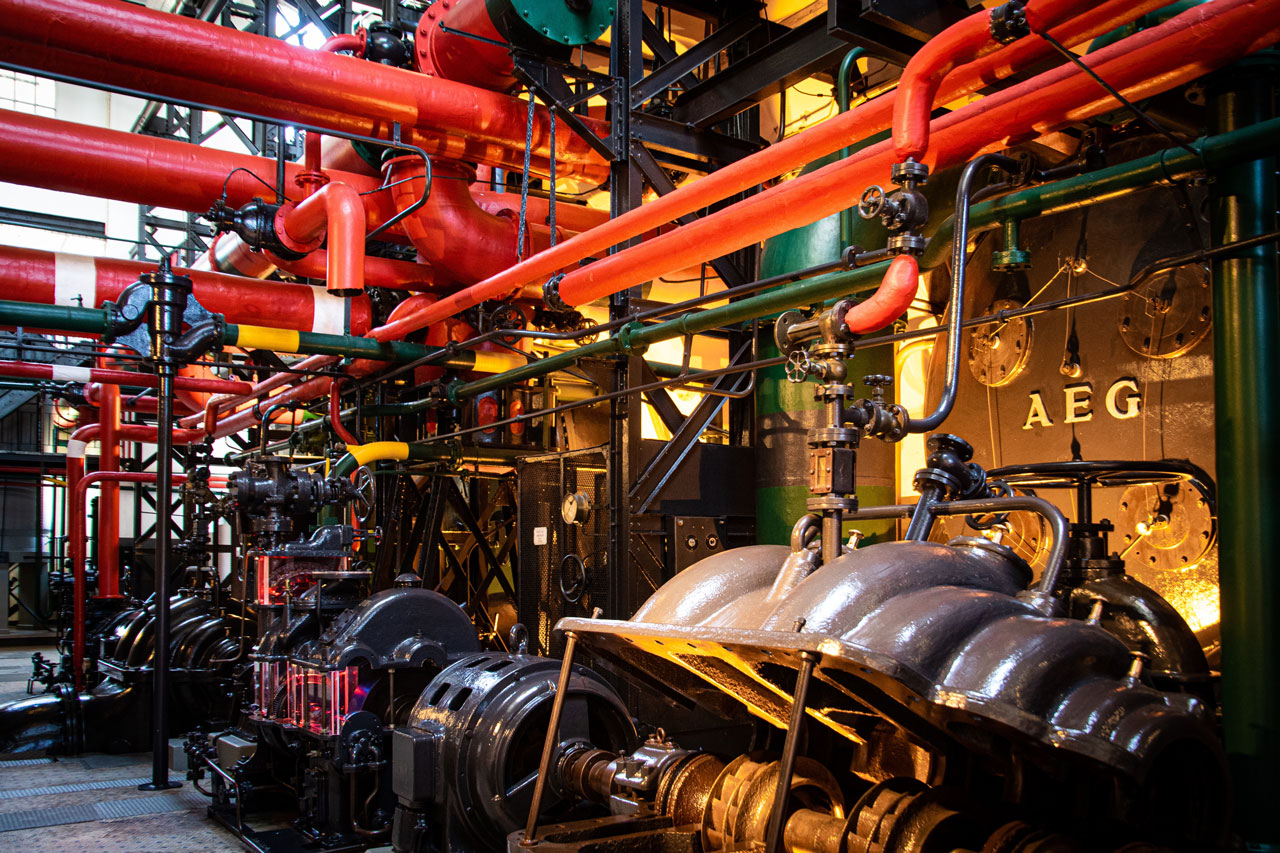

In the complex landscapes of chemical, oil, gas, and manufacturing industries, process piping systems form the vascular network crucial for the smooth and efficient transport of fluids, gases, and semi-solids. These systems, integral to operations, must adhere to stringent compliance standards to ensure safety, efficiency, and environmental protection. Compliance in process piping is not merely a regulatory requirement; it’s a foundational element that can dictate the operational integrity and profitability of an entire facility.

Mechanical contractors play a pivotal role in this context. They are the specialists who ensure that the design, installation, and maintenance of process piping systems meet all applicable standards and regulations. From adhering to the American Society of Mechanical Engineers (ASME) codes to following state-specific safety and environmental regulations, these professionals are tasked with a critical responsibility. By aligning process piping systems with industry standards, mechanical contractors not only safeguard the system’s functionality but also ensure that it operates within the legal and ethical frameworks set by governing bodies. Their expertise ensures that industries avoid potential fines, operational downtime, and safety hazards, contributing to the overall sustainability and success of industrial operations.

Understanding Compliance in Process Piping

Compliance in the context of process piping involves adhering to a set of prescribed standards and regulations designed to ensure the safety, efficiency, and reliability of piping systems. These regulations are crucial in industries that handle hazardous or critical materials, such as chemicals, oil, and gas, where any failure in the piping system can lead to significant safety risks, environmental damage, and financial losses.

Key Standards and Regulations Governing Process Piping:

- ASME B31.3 – Process Piping Code: Developed by the American Society of Mechanical Engineers, this code provides guidelines for the materials, design, fabrication, assembly, erection, examination, inspection, and testing of piping systems. It is specifically tailored to the processing and manufacturing industries, ensuring that the piping systems can withstand the operational stresses and hazards typical in such environments.

- API Standards: The American Petroleum Institute (API) sets numerous standards to regulate the quality and safety of petroleum industry equipment and operations. API standards cover various aspects of the oil and gas industry, including pipeline construction, maintenance, and inspection processes, ensuring that the infrastructure used is robust, reliable, and capable of preventing leaks and failures.

- OSHA Requirements: The Occupational Safety and Health Administration (OSHA) imposes regulations that ensure workplace safety, including specific standards for process piping. These requirements are aimed at protecting workers from potential hazards associated with process piping, such as exposure to high-pressure systems and hazardous materials. OSHA’s regulations compel facilities to maintain their piping systems adequately and to implement proper safety measures.

- Local and State Regulations: Beyond federal guidelines, process piping systems must also comply with state and local regulations, which can vary significantly from one region to another. These might include additional safety, environmental, or operational standards that address local concerns and conditions.

Understanding and implementing these standards and regulations is essential for maintaining the integrity and safety of process piping systems. Compliance not only ensures operational excellence but also safeguards the health of employees, protects the environment, and upholds the reputation of businesses by preventing accidents and failures. Mechanical contractors must be well-versed in these regulations to design, install, and maintain process piping systems effectively and legally.

Go deeper.

More process piping articles.

Common Compliance Challenges and Solutions in Process Piping

Ensuring compliance in process piping presents several challenges, particularly for mechanical contractors tasked with maintaining system integrity under varying operational and regulatory conditions. Here are some common challenges along with strategic solutions that help overcome these obstacles:

1. Dealing with Legacy Systems:

Challenge: Older piping systems often fall short of current standards and may pose safety risks or inefficiencies. Upgrading or retrofitting these systems while keeping the plant operational can be complex and costly.

Solution: Mechanical contractors often employ phased approaches to upgrades, integrating new technologies incrementally. Utilizing non-invasive diagnostic tools, such as ultrasonic flow meters and infrared cameras, helps assess the condition of existing systems without disrupting operations. Recommendations can then be made for gradual enhancements that align legacy systems with modern compliance requirements.

2. Adapting to New Regulations:

- Challenge: Regulatory environments are dynamic, with standards frequently updated to reflect new safety, environmental, or technological considerations. Keeping up with these changes can be daunting, especially for multi-national operations where regulations vary by jurisdiction.

- Solution: Contractors maintain active memberships in professional organizations like ASME and API, which provide updates on industry standards and regulatory changes. Continuous training programs for teams ensure that the latest practices are understood and implemented. Furthermore, deploying compliance software helps track regulatory changes and manage compliance documentation efficiently.

- Challenge: The materials used in piping systems must meet specific standards that can vary depending on the fluid being transported. Incorrect or substandard materials can lead to system failures or regulatory non-compliance.

- Solution: Mechanical contractors work closely with certified suppliers and use only materials that come with proper mill test reports (MTRs) verifying their compliance with the required specifications. Regular audits and material inspections are conducted to ensure ongoing compliance.

- Challenge: Upgrading piping systems to meet compliance standards can be expensive, and budget constraints may lead to corners being cut, risking non-compliance.

- Solution: Financial planning and project management tools are used to forecast the costs associated with compliance accurately. Mechanical contractors can also explore cost-saving measures that do not compromise safety, such as using alternative materials or methods that still meet regulatory requirements. Additionally, they can assist clients in identifying potential government grants or subsidies available for safety or environmental upgrades.

- Challenge: Comprehensive documentation is crucial for compliance, especially when audits are conducted. Maintaining detailed records of installations, repairs, inspections, and tests can be overwhelming.

- Solution: Implementing document management systems enables contractors to keep accurate records accessible for audits. These systems ensure that all documents are up to date and can be retrieved quickly and efficiently.

By addressing these challenges with proactive and strategic solutions, mechanical contractors ensure that process piping systems not only comply with current regulations but are also positioned to adapt to future changes, enhancing both safety and operational efficiency.

3. Ensuring Material Compliance:

4. Balancing Cost and Compliance:

5. Managing Documentation and Traceability:

The Benefits of Compliance in Process Piping

Maintaining compliance in process piping systems is not just about meeting legal requirements; it is a strategic approach that brings numerous benefits to industrial and commercial operations. These benefits not only enhance the immediate operational capabilities but also contribute to long-term success and stability. Here are the key advantages of upholding stringent compliance standards through a professional mechanical contractor:

Enhanced Safety

Primary Benefit: The most significant advantage of compliance is improved safety. By adhering to established standards and regulations, companies ensure that their piping systems are designed, installed, and maintained in a manner that minimizes the risk of accidents and failures. This is particularly crucial in industries handling hazardous materials where leaks or ruptures can lead to severe safety incidents.

Mechanical Contractor Role: Mechanical contractors play a crucial role in achieving this by conducting regular inspections, maintenance, and necessary upgrades that keep piping systems within safety standards, thus protecting not only the workforce but also the surrounding community and environment.

Operational Efficiency

Primary Benefit: Compliant piping systems are more efficient and reliable. By ensuring that installations are carried out correctly and maintained regularly, companies can avoid the downtime associated with repairs and malfunctions. Efficient systems also mean better energy use and reduced operational costs.

Mechanical Contractor Role: Contractors ensure that systems are optimized for performance from the start, using high-quality materials and the latest technology to minimize energy waste and enhance system longevity.

Avoidance of Legal and Financial Penalties

Primary Benefit: Compliance helps avoid costly legal troubles. Non-compliance can result in hefty fines, legal sanctions, and in severe cases, shutdowns. Staying compliant ensures that operations continue unhindered by legal complications.

Mechanical Contractor Role: Mechanical contractors keep track of evolving standards and ensure that all aspects of the system design and operation comply with current laws. This foresight protects companies from potential legal actions and financial losses.

Long-term Investment Benefits

Primary Benefit: Investing in compliance is a strategic move that secures the future of a business. Compliant systems are sustainable, with a longer lifespan and lower lifetime costs due to fewer breakdowns and repairs.

Mechanical Contractor Role: A dedicated mechanical contractor brings expertise in cutting-edge installation and maintenance techniques that extend the durability and efficiency of piping systems. Their continuous involvement ensures that systems not only meet current standards but are also adaptable to future regulations and technologies.

Enhanced Reputation

Primary Benefit: Companies known for strict compliance are viewed more favorably by regulators, clients, and partners. This reputation for reliability and safety can open up new business opportunities and partnerships.

Mechanical Contractor Role: Mechanical contractors help build this reputation by maintaining a clear record of compliance and excellence in system management, enhancing the company’s standing in the industry.

Maintaining compliance in process piping through a professional mechanical contractor not only ensures safety and efficiency but also positions a business for long-term success and growth. Investing in compliance is investing in the future stability and reputation of a company, making it a critical component of strategic operational management.

Ensuring Compliance Through Expert Mechanical Contracting

The role of mechanical contractors in ensuring compliance in process piping systems cannot be overstated. These professionals are integral to the design, installation, maintenance, and overall management of piping systems that meet the stringent standards required by regulatory bodies. By leveraging their expertise, businesses ensure that their operations are not only safe and efficient but also fully compliant with industry regulations.

Mechanical contractors provide an indispensable service by staying abreast of the latest developments in standards and technology. Their knowledge and experience in navigating complex regulatory landscapes are crucial for businesses that rely on robust and efficient process piping systems. These contractors ensure that every component of the system is optimized to meet both current and future compliance requirements, thereby safeguarding the company against potential legal, financial, and operational risks.

As businesses continue to face ever-tightening regulations and standards, the value of partnering with a skilled and knowledgeable mechanical contractor becomes increasingly apparent. Such collaboration is essential for maintaining the integrity and compliance of process piping systems, ultimately contributing to the long-term success and sustainability of the business.

We encourage all businesses to recognize the importance of compliance in their process piping systems and to partner with reputable mechanical contractors who can provide the expertise and attention to detail required to achieve and maintain these standards. Investing in such partnerships is not merely a regulatory necessity but a strategic decision that can define the future trajectory of your operations. Choose a contractor who understands the complexities of your industry and can deliver compliance-driven results that stand the test of time.

Our team is here to help.

Contact a project manager today!