Sanitary Pipe Materials

Sanitary pipes play a crucial role in a wide range of industries, ensuring the safe and efficient transportation of liquids and gases while maintaining the highest level of cleanliness and hygiene. In industries such as food and beverage, pharmaceuticals, biotechnology, and water treatment, sanitary pipes are particularly vital in preventing contamination and safeguarding public health. By adhering to strict material standards and design specifications, these pipes help preserve the quality and safety of the products being manufactured or processed.

The importance of sanitary pipes extends beyond these industries, as they also contribute significantly to the proper functioning of residential, commercial, and industrial plumbing systems. These pipes are responsible for carrying wastewater, sewage, and stormwater away from buildings and other facilities, protecting the environment and preventing the spread of diseases. In hospitals, medical facilities, and laboratories, sanitary pipes are indispensable in maintaining a sterile environment and minimizing the risk of infections. Therefore, understanding the role of sanitary pipes in various industries is essential to ensure the selection of appropriate materials and designs, ultimately leading to a safer and cleaner world.

What is sanitary piping? Read more

Importance of sanitary pipes in various industries.

Sanitary pipes are indispensable across a variety of industries, as they facilitate the hygienic and efficient transportation of fluids and gases. This ensures the highest standards of cleanliness and safety are maintained, which is particularly crucial in sectors such as pharmaceuticals, food and beverage production, biotechnology, and water treatment. In these industries, sanitary pipes help prevent contamination, which is essential for preserving the quality of the products being manufactured or processed, as well as for safeguarding public health.

The significance of sanitary pipes extends beyond these specific industries, as they are also vital components in residential, commercial, and industrial plumbing systems. Sanitary pipes carry wastewater, sewage, and stormwater away from buildings and facilities, thus protecting the environment and mitigating the spread of diseases. In settings such as hospitals, medical facilities, and laboratories, sanitary pipes play a critical role in maintaining a sterile environment and reducing the risk of infections. Consequently, recognizing the importance of sanitary pipes in various industries is key to ensuring the proper selection and implementation of suitable materials and designs, ultimately contributing to a cleaner and safer world.

Factors to consider when selecting sanitary pipe materials

When selecting sanitary pipe materials, it is essential to consider several factors to ensure that the chosen material meets the specific requirements of the application and maintains the highest standards of cleanliness, safety, and performance.

One of the most critical factors to consider is the material’s corrosion resistance. Sanitary pipes are often exposed to various chemicals, fluids, and gases that may cause corrosion, which can lead to leaks, contamination, or even failure of the piping system. Therefore, it is crucial to choose a material that offers excellent resistance to corrosion, such as stainless steel, PVC, or high-density polyethylene (HDPE).

Another important factor is the temperature and pressure resistance of the material. Different applications may require the transportation of fluids at varying temperatures and pressures, so the selected material must be able to withstand these conditions without degrading or losing its structural integrity. Materials such as stainless steel and copper offer high temperature resistance, while PVC and HDPE are better suited for lower temperature applications.

The compatibility of the sanitary pipe material with the specific chemicals and substances being transported is also an essential consideration. Some materials may react with certain chemicals, leading to contamination or damage to the pipe. It is important to choose a material that is chemically compatible with the substances being transported to avoid such issues.

Ease of installation and maintenance should also be taken into account when selecting sanitary pipe materials. Materials that are lightweight, easy to handle, and can be joined using simple methods, such as PVC or HDPE, can help reduce installation time and costs. Furthermore, materials that are easy to clean and maintain, like stainless steel, can ensure that the piping system remains hygienic and functions efficiently over time.

Lastly, cost is an important factor to consider when selecting sanitary pipe materials. While some materials like stainless steel and copper offer superior performance and durability, they may also come at a higher cost. It is essential to balance the material’s performance characteristics with the budget constraints to make an informed decision.

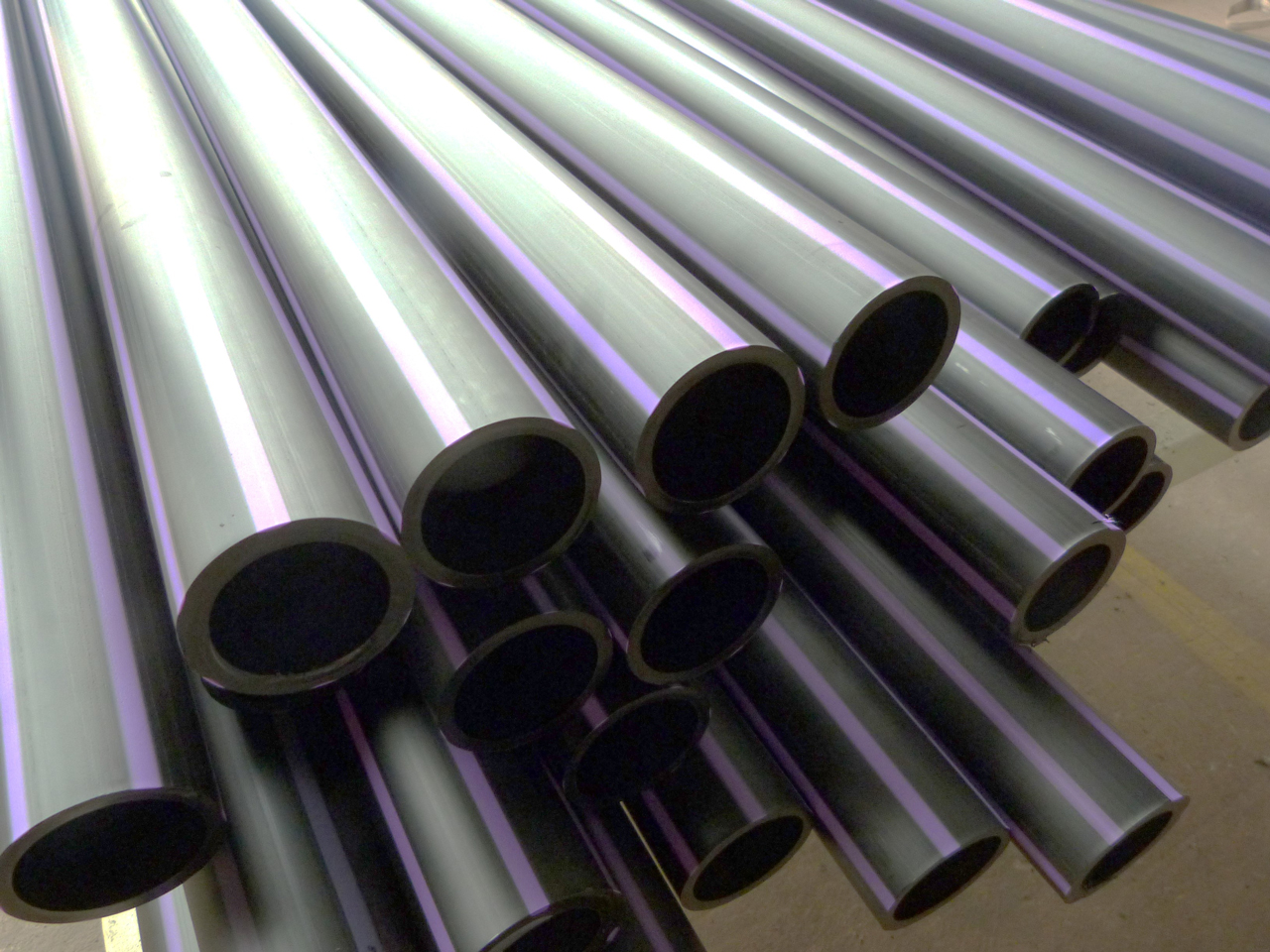

Stainless Steel

Common types and grades

Stainless steel is a popular choice for sanitary pipes due to its exceptional properties. It is an alloy made primarily of iron, with added chromium, nickel, and other elements. The most common types of stainless steel used for sanitary pipes are the 304 and 316 grades, with the latter offering greater corrosion resistance due to its higher molybdenum content. These austenitic stainless steel grades are known for their excellent weldability, forming properties, and overall performance in various applications.

Advantages

Corrosion resistance

One of the primary advantages of stainless steel sanitary pipes is their exceptional resistance to corrosion. The chromium content in stainless steel forms a passive layer of chromium oxide on the surface, which protects the material from rusting and other forms of corrosion. This makes stainless steel pipes suitable for applications involving exposure to various chemicals, fluids, and gases.

Durability

Stainless steel pipes are known for their strength and durability. They can withstand high pressures, temperatures, and mechanical stress, making them an excellent choice for long-lasting and reliable piping systems. Moreover, stainless steel pipes can maintain their structural integrity and appearance even in harsh environments, ensuring a longer service life.

Easy to clean and maintain

Another advantage of stainless steel sanitary pipes is that they are relatively easy to clean and maintain. The smooth surface of stainless steel pipes prevents the buildup of contaminants and allows for easy removal of dirt and debris. This ensures that the pipes remain hygienic and function efficiently over time. Furthermore, the passive chromium oxide layer on the surface of stainless steel pipes can self-repair if damaged, enhancing their durability and reducing maintenance requirements.

Disadvantages

Cost

One of the main disadvantages of stainless steel pipes is their relatively high cost compared to other materials, such as PVC or HDPE. The cost of stainless steel pipes depends on factors such as the grade, size, and manufacturing process. However, the long-term benefits of stainless steel pipes, including their durability, corrosion resistance, and low maintenance, often outweigh the initial investment.

Potential for galvanic corrosion

Stainless steel pipes may be susceptible to galvanic corrosion if they come into contact with other metals, such as copper or carbon steel, in the presence of an electrolyte. This occurs when the less noble metal (e.g., carbon steel) corrodes preferentially, while the more noble metal (e.g., stainless steel) remains protected. To avoid galvanic corrosion, it is essential to ensure proper isolation between dissimilar metals and take precautions during installation and design.

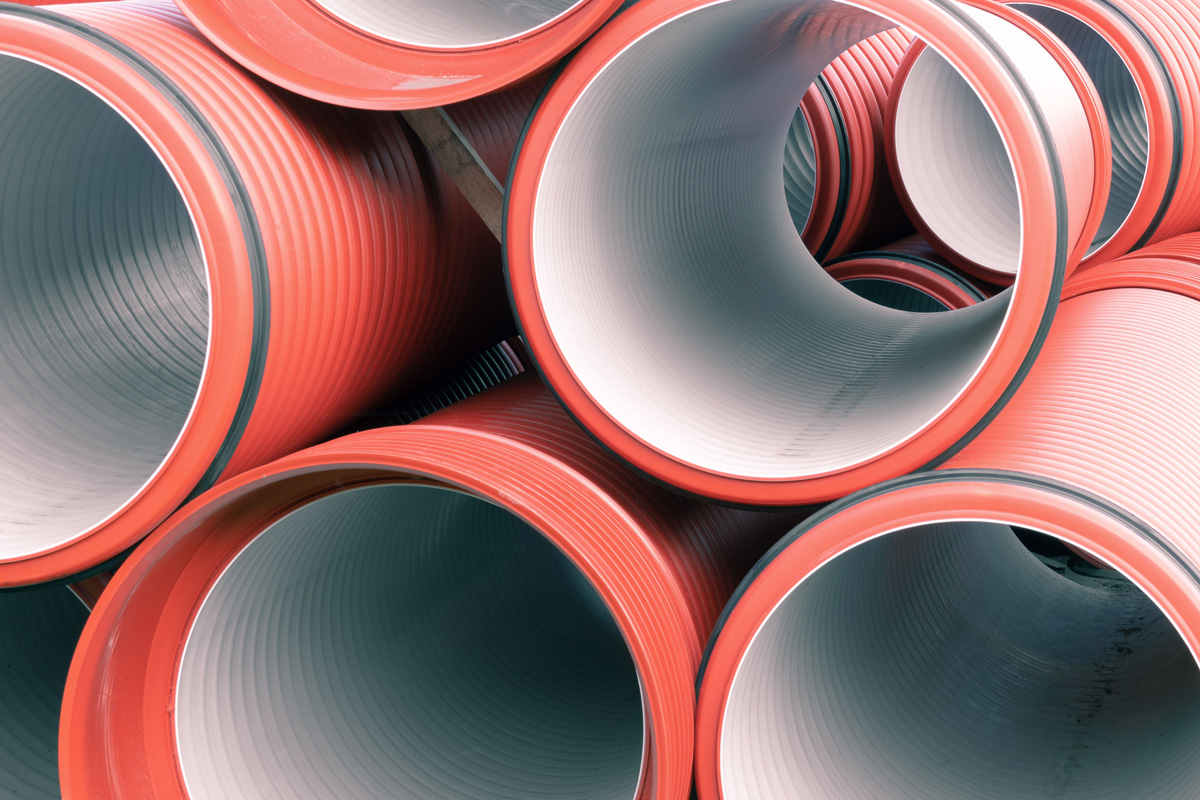

PVC and CPVC

Plastic Pipe lengths manufactured in Australia by Extruding HDPE material. Image courtesy of Wikipedia

Differences between PVC and CPVC

Polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (CPVC) are two widely used plastic materials for sanitary pipes. While both materials are similar in composition, CPVC is made by chlorinating PVC, which results in a more heat-resistant and chemically stable material. This difference in composition and properties makes CPVC more suitable for applications requiring higher temperature resistance or exposure to a wider range of chemicals.

Advantages

Lightweight

One of the most significant advantages of PVC and CPVC pipes is their lightweight nature. Their low density makes them easy to handle, transport, and install, reducing labor costs and installation time. The lightweight nature of these pipes also allows for easier modification and maintenance.

Corrosion resistance

PVC and CPVC pipes exhibit excellent resistance to corrosion, making them suitable for a wide range of applications. They do not rust, corrode or degrade when exposed to various chemicals, fluids, and gases. This makes PVC and CPVC pipes an ideal choice for environments where other materials, like metal pipes, may suffer from corrosion-related issues.

Cost-effective

PVC and CPVC pipes are generally more cost-effective than other sanitary pipe materials, such as stainless steel or copper. Their lower cost, combined with the ease of installation and low maintenance requirements, makes PVC and CPVC pipes an attractive choice for many applications, especially where budget constraints are a consideration.

Disadvantages

Lower temperature resistance compared to other materials

One of the main disadvantages of PVC and CPVC pipes is their lower temperature resistance compared to other materials like stainless steel or copper. While CPVC has a higher temperature resistance than PVC, it may not be suitable for applications with extremely high temperatures. In such cases, alternative materials should be considered.

Susceptibility to ultraviolet (UV) degradation

PVC and CPVC pipes can be susceptible to degradation when exposed to ultraviolet (UV) radiation from sunlight. Prolonged exposure can cause the pipes to become brittle, reducing their strength and potentially leading to failure. To mitigate this issue, PVC and CPVC pipes should be protected from direct sunlight or treated with UV-resistant additives and coatings during manufacturing.

Copper

Types of copper pipes and their applications

Copper pipes have been used for plumbing applications for centuries due to their excellent properties and performance. There are two main types of copper pipes: rigid copper and flexible copper. Rigid copper pipes are typically available in three wall thicknesses – Type K (thickest), Type L (medium thickness), and Type M (thinnest). They are commonly used for water supply lines, waste lines, and gas lines in residential and commercial applications. Flexible copper pipes, also known as soft copper or copper tubing, are primarily used for refrigeration, air conditioning, and gas distribution systems.

Advantages

Antimicrobial properties

Copper pipes possess natural antimicrobial properties, which make them an ideal choice for sanitary pipe systems. These properties inhibit the growth of bacteria, viruses, and fungi, helping to maintain a hygienic environment and prevent the spread of diseases.

Temperature resistance

Copper pipes have excellent temperature resistance, making them suitable for a wide range of applications, including hot and cold water supply, heating systems, and steam distribution. They can withstand extreme temperatures without losing their structural integrity, making them a reliable and durable option for sanitary pipes.

Longevity

Copper pipes have a long service life, often exceeding 50 years, due to their durability and resistance to wear and tear. This longevity makes copper pipes a cost-effective choice in the long run, despite their higher initial cost compared to other materials.

Disadvantages

Corrosion susceptibility

While copper pipes are generally resistant to corrosion, they can be susceptible to certain types of corrosion, such as pitting corrosion, which can cause pinhole leaks over time. Additionally, copper pipes may react with certain water chemistries, resulting in the formation of copper corrosion by-products, which can cause plumbing system issues and potential health concerns. To mitigate these risks, proper water treatment and monitoring of water chemistry are necessary.

Higher cost compared to other materials

Copper pipes tend to have a higher initial cost compared to materials like PVC, CPVC, or polypropylene. This higher cost may be a deterrent for some applications, particularly where budget constraints are a concern. However, it is essential to consider the long-term benefits of copper pipes, such as their durability, temperature resistance, and antimicrobial properties, which can offset the initial investment.

High-Density Polyethylene (HDPE)

Characteristics of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer made from petroleum. It is known for its excellent strength-to-weight ratio, flexibility, and resistance to chemicals and environmental stress cracking. HDPE is commonly used for various applications, including sanitary pipes, due to its impressive performance characteristics and cost-effectiveness.

Advantages

Corrosion resistance

HDPE pipes exhibit excellent corrosion resistance, making them ideal for sanitary pipe systems. They do not rust or corrode when exposed to chemicals, fluids, or gases, which allows them to maintain their structural integrity and performance over time. This makes HDPE pipes a suitable choice for applications where other materials, such as metal pipes, may be prone to corrosion-related issues.

Flexibility and durability

HDPE pipes are known for their flexibility and durability, which allows them to withstand various environmental conditions, ground movements, and pressure changes. Their ability to bend without breaking makes them an excellent choice for trenchless installations or applications with complex layouts. Furthermore, HDPE pipes have excellent impact resistance, which minimizes the risk of damage during handling, transportation, and installation.

Cost-effective

HDPE pipes are generally more cost-effective than other sanitary pipe materials like stainless steel, copper, or polypropylene. Their lower cost, combined with their ease of installation and low maintenance requirements, makes HDPE pipes an attractive option for many applications, particularly where budget constraints are a concern.

Disadvantages

Limited temperature resistance

One of the main drawbacks of HDPE pipes is their limited temperature resistance compared to materials like stainless steel or copper. HDPE pipes can withstand temperatures of up to 60°C (140°F) for continuous use, which may not be sufficient for applications with higher temperature requirements. In such cases, alternative materials should be considered.

Incompatibility with certain chemicals

While HDPE pipes are generally resistant to a wide range of chemicals, they may not be compatible with certain substances, such as strong oxidizing agents or solvents. This can lead to the weakening or degradation of the pipe material, which may compromise the performance and safety of the sanitary pipe system. To avoid these issues, it is essential to ensure that HDPE pipes are compatible with the chemicals being transported before installation.

Summary of key points

In this comprehensive guide, we explored various materials used for sanitary pipes, including stainless steel, PVC, CPVC, polypropylene, copper, and high-density polyethylene. Each material offers unique advantages and disadvantages, such as corrosion resistance, temperature resistance, durability, and cost-effectiveness. Understanding these characteristics is crucial for selecting the most suitable material for a specific application.

Encouragement to consult with experts for proper material selection

Given the complexity of sanitary pipe material selection, it is essential to consult with experts in the field, such as engineers, contractors, or manufacturers, to make an informed decision. These professionals can provide valuable insights, recommendations, and guidance based on their experience and expertise, ensuring that you choose the most appropriate material for your sanitary pipe system. By working with experts, you can optimize the performance and longevity of your piping system while minimizing potential issues and risks associated with material incompatibility or improper installation.

Importance of considering material properties for specific applications

The choice of sanitary pipe material plays a critical role in the overall performance, safety, and longevity of a piping system. Selecting the right material involves considering factors such as the temperature and pressure requirements, chemical compatibility, environmental conditions, and budget constraints. By carefully evaluating the material properties and their suitability for a particular application, you can ensure that the sanitary pipe system operates efficiently and reliably while minimizing the need for maintenance and repairs.

Our team is here to help.

Contact a project manager today!